Techmire > Products > Zinc & Lead > NTX Series > 44NTX

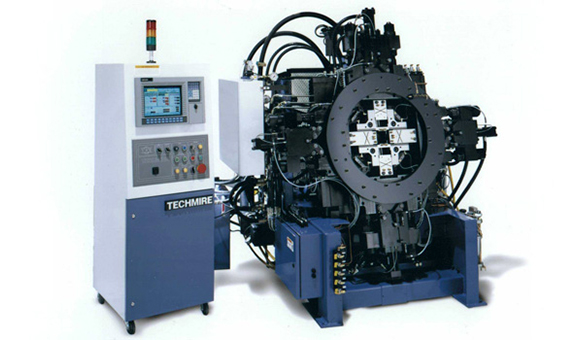

44NTX

The 44 NTX toggle mechanisms are mounted on massive toggle brackets, which are bolted to the platen of the machine. On the opposite side from the table, the four toggle brackets are joined together by a heavy ring. The resulting assembly is extremely rigid. Deflection under load is minimal.

The 44 NTX machine is capableof reaching a dry cycle speed of 3,600 cycles per hour and accepts tooling designed for Techmire 44NT and 44H series machines.

The NTX Series is Techmire's "premium" range of zinc and lead machines suitable for the widest range of applications in today’s demanding environment, and incorporates the latest advances in multiple-slide die-casting technology. The first NTX machine was introduced in 1999. The NTX Series features high capacity clamping systems, which are extremely rigid, and permit the use of greater metal pressures and injection velocities compared to the NT Series, resulting in superior surface finish and part density.

The NTX Series is complementary to the NT Series, and significantly increases the range of components that can be cost-effectively produced on Techmire machines.

| STANDARD | OPTIONAL | ||||

|---|---|---|---|---|---|

| SLIDES | Number of Die Motions | 4 | 8 | 8 | 8 |

| Die Size | 4.00 in x 4.00 in | 101.6 x 101.6 mm | |||

| Stroke of Each Die Section | 0 2.00 in | 0 50.8 mm | 0 3.00 in | 0 76.20 mm | |

| 1 x 1.50 in | 1 x 38.10 mm | 4 x 0 1.50 in | 4 x 0 38.10 mm | ||

| Ejector Stroke | 1.00 in | 25.4 mm | 1.97 in (max) | 50.04 mm (max) | |

| Maximum Total Die Opening | 4.00 in | 101.6 mm | 6.00 in | 152.4 mm | |

| INJECTION | Injection Plunger Diameter | 1.625 in | 41.27 mm | 1.00 / 1.25 / 1.875 in | 25.4 / 31.75 / 47.625 mm |

| Injection Cylinder Diameter | 3.25 in | 82.55 mm | 2.00 in / 2.50 in | 50.80 / 63.50 mm | |

| Injection Plunger Stroke | 2.36 in | 60.00 mm | |||

| Maximum Dry Shot Speed at 1,000 psi/70 bars* | 55 in/sec | 1.40 m/sec | 85 / 150 in/sec | 2.16 / 3.81 m/sec | |

| Injection Capacity (max.theoretical)* | 17.3 oz | 490 g | 6.6 / 10.3 / 23.1 oz | 187 / 292 / 655 g | |

| Shot Weight (max.recommended)* | 8.65 oz | 245 g | 3.3 / 5.1 / 11.5 oz | 93 / 146 / 327 g | |

| Metal Pressure (max.recommended)* | 4000 psi | 275.8 bars | |||

| Nozzle Heater | 3.2 kW | 3.2 kW | |||

| HYDRAULICS* | Hydraulic Line Pressure (max) | 1867 psi | 128.6 bars | ||

| Hydraulic Tank Capacity | 30 gallons | 113.5 liters | |||

| Clamping Force | 25 tons | 22.67 tonnes | |||

| Dry Cycle Speed / Hour | 3600 | 3600 | |||

| Motor Power | 20 HP | 14.9 kW | |||

| MELT POT (electric) | Heaters | 25.2 kW | 25.2 kW | ||

| Capacity of Melt Pot | 400 lbs | 181 kg | |||

| Melt Rate / Hour | 218 lbs | 99 kg | 258 lbs | 117 kg | |

| MELT POT (Gas) | Burner | 110,000 Btu/hr | 32.2 kW | ||

| Capacity of Gas Heated Melt Pot | 400 lbs | 181 kg | |||

| Melt Rate / Hour | 232 lbs | 105 kg |

* Dependent upon machine configuration