Techmire > Products > Zinc & Lead > NT Series > 66NTX

66NTX

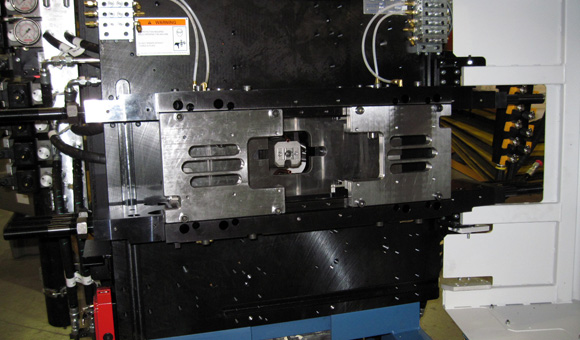

Building on its expertise as the world’s leading producer of high speed, multiple-slide diecasting machines,TECHMIRE has introduced the 66 NTX model, featuring two-slide toggle mechanisms mounted on the right- and left-hand side of the crosshead.

The crosshead holding the complete mold is capable of accepting two die segments and sliding shanks of 160 mm x 160 mm or 6.3 x 6.3 inches and up to four (4) additional hydraulic functions driving cores in and out of the cavity.

The toggle cylinder driving the slide could be a direct acting or an adjustable end stroke cylinder improving the machine speed by 10%. Smaller size cylinders could be also used to drive different feature in or out and to lubricate the mold cavity.

The NTX version has a stronger double hinge yoke into the toggle system with added links and better guiding. This improved design set the pressure on the internal pins evenly when locking and reduce strains on bushings

The 66 NTX toggle clamping system or crosshead of six (6) holding tie bars per toggle, provide a clamping force of 33tn or 30 metric ton of holding pressure between the die halves. The force applied by the toggle bracket set the holding force into the center and onto the die halves.

The 66 NTX offer higher productivity with the proven benefits of a two-slide locking system and multiple hydraulic functions with parting- line injection technology. Cores can be pulled at any angle, in any direction, to provide complex die castings to keep tooling costs at a minimum.

The machine features a die size ideal for producing zinc components weighing a few grams up to 327 grams (11.5 oz) with tight tolerances at fast cycle speeds.

Techmire's NTX line of multiple-slide, hot-chamber machines have the capability to economically produce complex zinc and lead parts. Machines feature fully automatic operation for the highest degree of repeatability and reliability;

Parting line injection to significantly improve the shot-weight to part-weight ratio, by eliminating the sprue and reducing the runner system to a minimum. This results in savings in raw materials, lower energy costs, elimination of secondary trimming operations and faster cycle speeds.

Techmire world leader in the design and manufacture of multiple-slide die-casting systems for precision components in zinc, lead and magnesium alloys.

| STANDARD | OPTIONAL | ||||

|---|---|---|---|---|---|

| SLIDES | Number of Die Motions | 2 | 8 | 8 | |

| Die Size | 6.30 x 6.30 in | 160.0 x 160.0 mm | |||

| Stroke of Each Die Section | 3.15 in | 80.0 mm | 0 3.15 in | 0 80.00 mm | |

| Ejector Stroke | 1.34 in | 34.00 mm | 3.12 in (max) | 79.25 mm (max) | |

| Maximum Total Die Opening | 6.30 in | 160.00 mm | |||

| INJECTION | Injection Plunger Diameter | 1.625 in | 41.27 mm | 1.00 in | 25.4 mm |

| 1.25 in | 31.75 mm | ||||

| 1.875 in | 47.625 mm | ||||

| Injection Cylinder Diameter | 3.25 in | 82.55 mm | 2.00 in | 50.80 mm | |

| 2.50 in | 63.50 mm | ||||

| Injection Plunger Stroke | 2.36 in | 60.00 mm | |||

| Maximum Dry Shot Speed at 1,000 psi/70 bars* | 55 in/sec | 1.40 m/sec | 85 in/sec | 2.16 m/sec | |

| 150 in/sec | 3.81 m/sec | ||||

| Injection Capacity (max.theoretical)* | 17.3 oz | 490 g | 6.6 oz | 187 g | |

| 10.3 oz | 292 g | ||||

| 23.1 oz | 655 g | ||||

| Shot Weight (max.recommended)* | 8.65 oz | 245 g | 3.3 oz | 93 g | |

| 5.1 oz | 145 g | ||||

| 11.5 oz | 327 g | ||||

| Metal Pressure (max.recommended)* | 4000 psi | 275.8 bars | |||

| Nozzle Heater | 3.2 kW | 3.2 kW | |||

| HYDRAULICS* | Hydraulic Line Pressure (max) | 1350 psi | 93 bars | 1867 psi | 128.6 bars |

| Hydraulic Tank Capacity | 30 gallons | 113.5 liters | |||

| Clamping Force | 30 tons | 26.7 tonnes | |||

| Dry Cycle Speed / Hour | 2700/hr | 2700/hr | |||

| Motor Power | 15 HP | 11.2 kW | 20 HP | 14.9 kW | |

| MELT POT (electric) | Heaters | 25.2 kW | 25.2 kW | ||

| Capacity of Melt Pot | 400 lbs | 181 kg | |||

| Melt Rate / Hour | 218 lbs/hr | 99 kg/hr | 258 lbs/hr | 117 kg/hr | |

| MELT POT (Gas) | Burner | 110,000 Btu/hr | 32.2 kW | 150,000 Btu/hr | 44.0 kW |

| Capacity of Gas Heated Melt Pot | 400 lbs | 181 kg | |||

| Melt Rate / Hour | 232 lbs/hr | 105 kg | 318 lbs/hr | 144 kg/hr |

* Dependent upon machine configuration